Quartz Countertops

Quartz countertops not only looks beautiful, but is also resistant to destruction. In the production of a kitchen, sooner or later it comes to the countertop. This element of the kitchen interior not only plays the role of a decorative detail, but also serves a practical purpose. Of course, the owners use special cutting boards when cooking, but during use, you can often damage the countertop. That is why it is very important that the surface is not only beautiful, stylish and popular with the inhabitants, but also that it is durable and resistant to mechanical and chemical damage. Recently, artificial types of stone have been especially popular.

What is quartz for countertops, what is it made of

Quartz stone is a material based on natural quartz and synthetic resins. Quartz agglomerate is a sheet material. Quartz agglomerate sheets (slabs) are often called slabs.

Depending on the brand, the quartz agglomerate contains from 90 to 95% crushed quartz (quartz sand and quartz powder). Resin is used as a binder (4-9%). To obtain different colors and decors, color pigments are added (about 1% of the composition).

The high content of natural quartz makes the quartz agglomerate comparable in hardness to natural stone. Its processing requires stone cutting, polishing machines and other equipment that is used in the processing of natural stone.

Quartz agglomerate has increased wear resistance and is resistant to mechanical damage. According to these parameters, it is not inferior to natural granite.

An important feature of the quartz agglomerate is the absence of microcracks and pores. This compares favorably with natural stones (marble, granite, travertine and others), the natural porous structure of which is subject to persistent pollution, destruction and requires special care for products made from them.

The non-porous surface of the quartz agglomerate resists the absorption of moisture, dirt and stains, as well as the development of microbes and mold. Quartz surfaces are environmentally friendly for indoor use: quartz agglomerate does not emit radon, does not have a background radiation.

Externally, quartz agglomerate is very similar to natural stone, its polishing has the same natural noble luster. Quartz kitchen countertops gained popularity at the beginning of this century.

In addition to countertops, quartz agglomerate is used as a cladding material for interiors, in the manufacture of kitchen and other types of countertops, as well as various pieces of furniture and interiors.

The high strength and wear resistance of quartz agglomerate makes it possible to use it not only for residential premises, but also for public buildings. This material has proven itself as a cladding material for bathrooms, sales areas and halls, for floors and steps of shopping and entertainment centers, train stations and airports.

Pros and cons of quartz countertops

Pros:

The main advantages of quartz agglomerate are its strength. This quality is ensured due to the presence of natural stone and quartz sand in the crumbs. Polyester resin is used to hold these components together. Due to this composition, quartz agglomerate is an order of magnitude stronger than any natural stone. Separately, it should be noted that the surface of such a tabletop is resistant to scratches and chips. It can be used to cut food without the need for a board. Hot dishes can also be placed on this stone. Due to its resistance to high temperatures, there will be no marks or stains on the surface.

Quartz bathroom countertops are also easy to clean. The agglomerate can be washed with any available means. This stone is resistant to the negative effects of dyes, chemicals, etc. At the same time, it easily resists any household loads.

Other benefits worth noting:

- no need for additional processing after installation;

- non-porous stone surface, resistant to the appearance and reproduction of microorganisms;

- long service life (with timely care and proper operation, it can last more than a dozen years);

- refined and prestigious appearance (visually quartz agglomerate is no worse than natural stone);

- solidity of the structure;

Cons:

One of the main disadvantages is the cold surface of the countertops. The disadvantages also include the fact that quartz products are difficult to restore and cause problems during transportation. Other disadvantages include a low level of plasticity, instability to the effects of abrasive substances and a relatively high cost. However, the strength, aesthetics and variety of colors of the quartz agglomerate countertops cover all of the above disadvantages.

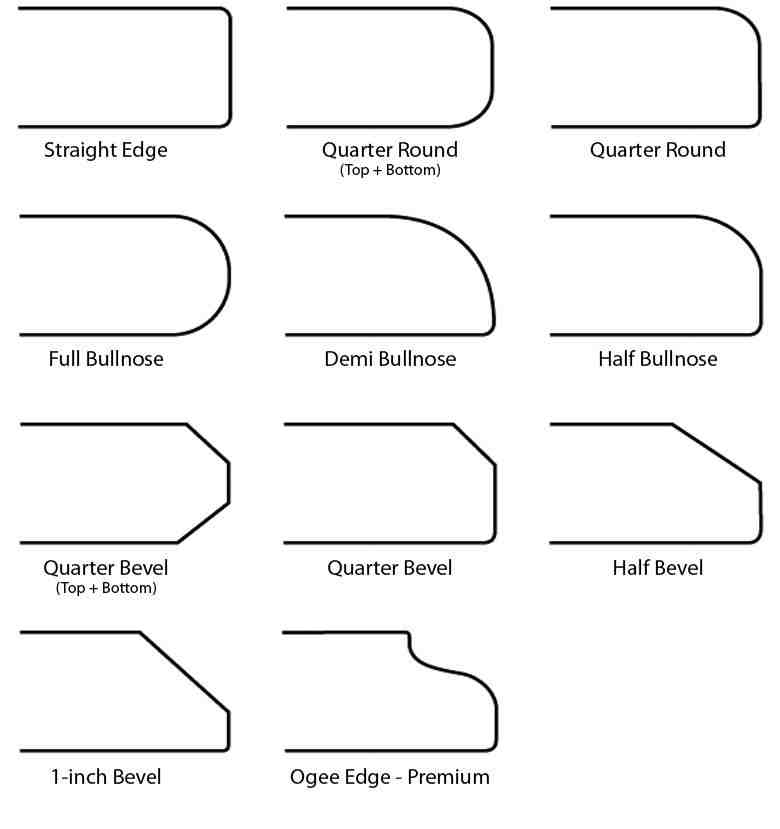

Quartz Countertop Edges

Quartz Countertops Benefits

One of the main advantages of quartz stone (or quartz agglomerate) is that these are slabs manufactured from natural quartz chips in the factory. Just imagine: your stone countertop will consist of 93-97% natural material and 3-7% high-quality polyester resin and natural pigments. This is a combination of the main advantages of natural material and advanced technologies that are constantly being improved.

Quartz agglomerate is devoid of all the disadvantages of natural natural stone:

- there are no pores, which means that you can be sure that your kitchen countertop is hygienic and that 99% of existing bacteria have no chance to penetrate the material

- plain texture. Those. the slabs of quartz stone have no tint. If you want to order a kitchen countertop from several sheets of material, then it is guaranteed to be of one tone. Which can never be in natural stone, because in nature there are no two identical textures

- natural stone is susceptible to chips and cracks, while quartz composite, due to the presence of 3-7% polyester resins in its composition, is resistant to mechanical damage

- unlike natural stone, quartz agglomerate has no natural background radiation

The kosher certification of a quartz stone confirms these benefits. After all, the fact of having such a certificate is in itself a guarantor of the quality and hygiene of the material. Those. if you want to buy a quartz stone countertop, then know that it will be 100% free from components harmful to humans.

Why quartz countertops are better than granite or marble countertops

What is the difference between quartz stone and marble and granite?

- Wide color palette. Natural granite and marble are usually gray with some shades, while quartz agglomerate, due to the possibility of adding dyes, can be of almost any color.

- High strength. In the production of artificial stone countertops, quartz chips are used, which are bonded with special polyester resins, which allows for increased hardness and strength, even compared to granite and marble.

- Resistant to chemical attack. The absence of a porous surface of composite quartz tiles makes it impossible for aggressive substances to penetrate inside, which could lead to the destruction of the material.

- Plastic. The addition of polyester resins makes the quartz agglomerate more ductile and less brittle than natural quartz, granite and marble.

The cost of composite quartz deserves special attention. Products made from natural granite and marble are much more expensive than quartz agglomerate, which is another distinctive feature that makes it a popular building and finishing material, in demand not only among professionals, but also among those who decided to make repairs at home.

Colors and textures of quartz countertops

The specific palette of colors and textures for quartz countertops depends on the manufacturer and can vary significantly.

Typical surface textures:

- Completely smooth surface

- Slightly roughened, velvety surface (like Suede by Silestone)

- Surface with a deep, clearly perceptible rough texture (like Silestone's Volcano texture)

Quartz colors for countertops also come in a wide variety. Here you can find both imitation of natural stone - marble, and very uniform colors, including artificial dyes.

Typical surface colors:

- White

- Gray

- Black

- Brown

- Yellow-golden

- Cream

- Green shades

- Blue shades

- Shades of red flowers

Typical Quartz countertops colors palette:

Quartz countertops cost

Quartz kitchen countertop is a stylish and functional addition to the interior. It has excellent aesthetics, long service life and high performance. The product does not require complex maintenance, it is resistant to external factors.

Many are wondering how much a quartz countertop costs per square foot. The cost of the product is calculated individually, the price depends on the manufacturer of the stone, the volume of the order, the design choice of the client.

The price per square foot of quartz stone for countertops ranges from $50 to $100.

The cost of a quartz stone countertop may depend on: the complexity of the project, the amount of material, side, edge, wall apron.

How quartz countertops are made

Quartz stone is designed to imitate natural stone both visually and tactilely, without having its operational drawbacks.

Quartz stone is produced using a special technology. Manufacturing technology consists in a patented process of vacuum vibrocompression. The quartz particles are bound together by an adhesive accelerator that creates a silicon-dependent bond. Vibration compaction in vacuum brings the particles as close to each other as possible in such a way that it allows you to create an extremely strong and non-porous material with the use of a minimum amount of binder paste. The result is a uniquely low water absorption rate of 0.02%. Thus, after going through a chemical process determined by technology, a unique composite material is obtained that does not exist in nature.

The main component in the composition of the quartz agglomerate is an aggregate of stones of various rocks of siliceous origin. It can be quartz, basalt, quartzite, dolomite, marble, siliceous sand, granite and other materials that make up 94-97% of the mixture. Aggregates can be of different size and shape of the fraction, depending on the desired end result. 3% resin binders (unsaturated polymer resins or organic binders, with the addition of a hardening accelerator) are required to fill the voids between minerals and bond the stone particles together.

To give the final product a specific design, the mixture is colored with metallic oxide pigments. Further, depending on the design, decorative elements are added to the mixture: brass, glaze, glass of various shades, mirror, mother-of-pearl. Special laboratories at manufacturing plants are constantly working on the creation of exclusive designs. The surface treatment of the sheet can be smooth, glossy, matte, embossed, with a certain repeating pattern.

Quartz Countertop Care

Cleaning Quartz can be deep and daily. Daily cleaning allows you to maintain a beautiful appearance for more than one decade. Deep cleansing helps get rid of stubborn stains. If you properly care for the countertop, then its appearance can remain in its original state for 20-40 years.

If you clean the tabletop every day, the surface will not change color even after 10 years. Use warm water and a surfactant detergent for daily wiping. It is worth refraining from using hard brushes or metal scrapers, as this can lead to a violation of the integrity of the coating. It is best to use soft sponges and products that do not contain:

- Chlorine.

- Abrasive components.

- Alkali.

The above components can cause damage to the quartz agglomerate, so you should refrain from using drugs that are not intended for artificial stone. If coloring liquids have spilled on the surface or heavily pigmented products have been lying, then it is better to immediately wipe the countertop with special compounds. Greasy stains that occur during cooking can be removed with a sponge and dishwashing detergent.

There are a number of products that are designed for deep cleaning of quartz. On light types of artificial stone, dirt easily remains from various products:

- Turmeric.

- Beets.

- Guilt.

- Tea.

- Coffee.

- Greenery.

- Berries.

If the stain was not removed in a timely manner, then cleaning the surface can be significantly complicated. You can use bleach on white surfaces, but if the color of the countertop is different, then you should not use bleach.

The main rule about caring for a quartz countertop is not to leave a stain for long. The longer the dirt eats into the surface, the more difficult it is to remove it. For example, a wine stain is clearly visible on a light quartz stone; if it is not removed for several days, it will remain on the surface. The dirt is quickly absorbed into the polyester resin, which is used as a binder.

Important! It is very difficult to remove green stains if they have dried on a quartz surface.

If the stain has appeared on the countertop for a long time, you can try removing it with rubbing alcohol. It is better to use undiluted alcohol, because the higher the degree, the easier it is to deal with the pollution. The stain must be soaked several times in alcohol. If this does not help, you will have to use a cardinal method - polishing with a special tool, with which a thin layer of quartz is removed, and with it the pollution. The worktop is then polished to restore its shine while protecting it from damage. Of course, this is an extreme measure; it is used only when other methods have proved ineffective.

Other helpful tips for caring for your quartz countertop:

- grease stains can be easily removed with dishwashing gel and a hob brush;

- a special product is required to remove limescale;

- it is strictly forbidden to clean the quartz surface with aggressive bleaching agents if the composition contains abrasive particles;

- it is not recommended to use alkali-based products, soda, as well as compositions containing chlorine;

- be sure to purchase holders for hot dishes, since the quartz surface deteriorates from exposure to high temperatures;

- wet soft wipes are perfect for daily care; they are moistened with clean water, which is safe for a quartz surface;

- When choosing a product for caring for a quartz countertop, carefully study the composition; it should not contain hydrofluoric acids, trichloroethane or methylene chloride.

Quartz is sensitive to mechanical stress, so if possible, avoid hitting with heavy objects. If you find a chip or crack on the countertop, most likely you will have to invite specialists who have special tools available.

F.A.Q.

Why do our customers choose quartz kitchen countertops?

- Quartz worktops combine quality and elegance. They are great for modern or modern kitchens.

- Quartz surfaces are non-porous and handcrafted from a material that is stronger than granite.

- Quartz countertops are very durable. Almost any detergent is suitable for cleaning them.

- Quartz surfaces are handcrafted from quartz, one of the most durable natural minerals that requires no additional sealing and is extremely stain resistant.

Can the stone be used outdoors?

Some of our customers have installed an outdoor quartz stone, but we cannot recommend this type of use of our products as they are not certified in terms of UV resistance.

Does quartz stone need to be sealed?

Not necessary. Quartz stone is completely non-porous, so there is no need for sealants or waxes.

How to remove permanent stains?

Using a soft cloth dipped in warm water and liquid soap. Use non-abrasive household cleaners if necessary (they will not strip the surface of the surface). To remove adhering food particles, chewing gum, nail polish or dried paint, first scrape them off with a plastic spatula and then use a soft, damp cloth to remove any remaining dirt. For particularly stubborn stains, use 3M Scotch-Brite Universal Wipes in combination with a detergent recommended by your local quartz stone distributor.

Can quartz stone be used as a cutting surface?

Thanks to its non-porous structure, quartz stone is ideal for use in the kitchen or in food preparation areas, as it slows down and prevents the growth of bacteria. The main component of countertops is quartz, so they do not develop mold or bacteria. Quartz stone has been certified by the American Institute of Sanitation and Hygiene (NSF) in accordance with the NSF 51 international sanitation standard and is therefore approved for installation in hospitals, restaurants, hotels and other environments.

How to preserve the natural beauty of quartz products?

Simply wipe the surface with a damp cloth and warm soapy water or a paper towel. Grease, dirt, hairspray or makeup stains will disappear! By routine cleaning with a damp cloth, your polished surface will always look like new. To keep your surface from dulling, use only a non-abrasive detergent.

Is quartz stone resistant to temperature?

Quartz stone is much more resistant to temperature than other surfaces, including most types of granite, marble and sandstone. It does not change its properties up to temperatures of 150 ° C (300 ° F), however, like any other stone, it does not tolerate sudden changes in temperature. Therefore, we absolutely do not recommend placing hot pots or pans on the surface. We also recommend placing electrical kitchen appliances such as deep fryers, steamers, or toasters on the base.

Is quartz stone resistant to dirt?

Quartz stone is non-porous due to the physical properties of its main component, quartz. Quartz is an inert, non-absorbent mineral, so quartz surfaces are resistant to fruit juices, liquid food colors, coffee, tea, wine and other beverages. It is important to note that the resistance to contamination due to the high quartz content makes the use of chemical sealants unnecessary.

Is quartz stone durable?

Quartz stone is resistant to impacts, chips, scratches and dirt. However, as with any material, strong impact or crushing can cause mechanical damage.

Maryland: 1954 Halethorpe Farms Rd #500, Halethorpe, MD 21227

Florida: 6850 Lyons Technology Cir, Coconut Creek, FL 33073

Services

Stone catalog

Where we work

Follow Us

Recent Articles

- Quartz Countertops in Boca Raton: Top Quality Just Minutes Away

- Best Quartz Styles for Coastal Florida Homes

- Why Florida Homeowners Choose Quartz for Their Homes and Apartments

- The Psychology of Color in Quartz Countertops: What to Know in 2025

- Top 5 Myths About Quartz Countertops — Debunked: What to Know in 2025

- Sustainable Quartz Surfaces: What to Know in 2025